There’s no substitute for high-quality materials in manufacturing. Just like a chef needs to start with fresh ingredients to make a delicious meal, metal fabricators require certified, industrial-grade metals to create machinery that’s reliable, durable, and safe. There’s no substitution.

Different projects, however, require different types of raw materials. Some metals lend themselves to certain applications, and so a crucial part of the product design process is sourcing and selecting the right metals for the job.

Robycs Technology supports businesses in Sydney requiring metal fabrication by connecting them with specialist capabilities across forming, cutting, and CNC machining for industrial applications such as manufacturing and energy production. The focus is on ensuring access to high-quality fabrication outcomes aligned with demanding operational requirements.

Selecting the right materials is a critical part of this process. This section explores common raw materials used in the production of customised mechanical components and why material choice plays an important role in performance, durability, and application suitability.

Types of Metals

These are some of the most common types of metals that we use for metal fabrication.

Iron: This most abundant metal on earth has a long history of over three thousand years of human use! And we’re not just talking about cast iron skillets. Since it rusts easily, we don’t often find much iron on the factory floor, though most iron is used to manufacture our second metal.

Steel: An alloy of iron and carbon, steel is the most common metal for industrial use cases. Flexible, strong, and affordable, we can’t even begin to list all the possible uses for steel. This metal is truly the backbone of our modern world. There are also several notable types of steel, including stainless steel, which contains aluminium, chromium, and high carbon levels. Stainless steel is highly corrosion-resistant, making it ideal for its long lifespan and low required maintenance. Carbon steel, on the other hand, is harder than other types of steel because it contains the highest quantities of carbon, though it has less ductility and malleability than other steels.

Aluminium: Light, rugged, and versatile, this metal is indispensable to industry because of its ductility and high strength to weight ratio, which makes it perfect for applications like aviation that need lightweight materials. This metal is also used for low-temperature applications, such as aerospace or refrigeration, because it doesn’t perform well above 200 degrees Celsius.

Copper: As one of the best and cheapest conductors of electricity, copper is ubiquitous with electrical components and wiring. It’s also tough, malleable, and resists corrosion; making is very useful for harsh environments like heavy industry.

Brass: We often find this alloy of copper and zinc in everything from gear components to pipe fittings to nuts and bolts. And, of course, it’s great for creating instruments, but that’s another story.

Bronze: This copper alloy has seen use since around 3500 BC, this metal weighs more than steel, is stronger than copper, and has a lower melting point.

Magnesium: The most important feature of this metal is that it’s lighter than any of our other industrial-grade metals. This makes it useful for applications where we need lightweight stiffness over strength, such as for aircraft, automobile parts, or rapidly rotating motors.

The Raw Materials

Metal arrives to our shop floor in Sydney in a variety of shapes and sizes. The kind we use most is a flat metal that’s been rolled or pressed into thin, flat pieces. There are three main types of flat metal. Foil or leaf is the thinnest, while sheet metal is the most common and has a thickness of less than 6mm. Plate metal is the third type of flat metal, and this includes any flat metal thicker than 6mm.

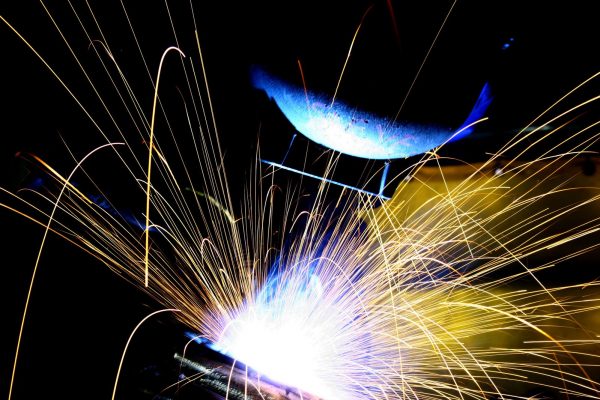

High-quality welding wire plays a critical role in metal fabrication outcomes. Different types of weldable metals are used in wire form to securely join metal components, with material selection tailored to the application, strength requirements, and fabrication process involved.

There are also other round or irregularly raw materials that includes shot, pellets, pieces, chips, and ingots. Each of these shapes lends itself to certain applications, and so it’s important to have a good source for each of them.

We Never Compromise on Material Quality for Fabrication Projects

Robycs Technology supports businesses by helping ensure access to high-quality raw materials through carefully vetted supply chains. Materials used in metal fabrication are expected to meet recognised international and Australian standards, including requirements set by the International Organization for Standardisation (ISO), particularly their ISO 9001: 2015 and AS 9102 quality frameworks.

Material quality is critical to safety and performance. Low-grade or non-compliant metals can introduce significant risks in industrial applications, which is why priority is placed on sourcing materials from reputable Australian suppliers such as BlueScope Steel, known for supplying high-grade steel to local industry for more than a century. Safety, consistency and reliability remain central considerations.

Access to strong, durable metals at a reasonable cost is balanced with long-term sustainability. This includes working with suppliers whose values align with continuous improvement and responsible manufacturing, including organisations such as Rio Tinto for aluminium and related materials. All raw materials are subject to quality assurance checks before fabrication to ensure suitability for demanding production environments.

To learn more about how custom metal components are supported for Australian manufacturing and industrial applications, explore Robycs Technology’s Sydney metal fabrication capabilities.