Start boosting your output with Industrial Robots

Is your business still using manual labour for repetitive tasks? Join thousands of successful manufacturers worldwide and future-proof your business by upgrading to the next generation of robotic systems. Robycs Technology specialises in integrating high-quality KUKA robots into the operations of Australian Businesses to give them the leading edge. We're also experienced with other major Robotic brands including ABB, FANUC, Universal Robots and Mitsubishi.

Palletizing

Prevent workplace injuries and boost efficiency. Our palletising robot systems can stack boxes, cartons, bags of all sizes onto pallets.

Welding

Get pinpoint accuracy and precision for repetitive welding jobs. Robotic welders can improve manufacturing efficiency and safety

Cutting

Robotic cutting and milling systems are much more accurate than manual alternatives as well as faster and more flexible than CNC.

Gripping

Save time and eliminate manual handling stress from your workforce. Move and position all types of products with suction grips, clamps and more.

Expert Support, Service and Maintenance for all types of Robots

Robycs Technology provides support for all types of industrial robots, including:

- Outstanding after-sales support for our robotic systems

- Preventative and scheduled robot maintenance

- Priority breakdown and 24-hour support for robot faults

We service and support all types of robot brands, including KUKA, ABB, UR, FANUC, Mitsubishi and more.

Our Sydney-based industrial electrical maintenance team can also help with all types of integration faults between your robotic systems and other equipment in your facility.

Move Inventory Faster with our Gripping and Palletising Robots

Using the latest in Robotic Automation technology, Robycs Technology can help you improve your production or manual handling industrial processes. We have worked with clients across the Sydney region, and elsewhere in Australia to help them take advantage of industrial robots and robotic technology in their business.

We believe in providing solutions for our clients with cutting-edge control systems that increase productivity without sacrificing accuracy. Our motion-related services ensure any client need is met with precision, speed, flexibility, and complete accuracy - every time.

Design, Installation and support for all Automated Robotic Systems

From design to completion, Robycs Technology can help your business to implement automated robotic systems to increase your productivity. When combined with our innovative automation solutions, we can help you streamline your manufacturing operations. We install and support the top global brands in industrial robotics:

- Universal Robotics UR5 robots

- FANUC robots and robomachines

- KUKU robotics products

We can also help you to upgrade your current robotic systems including:

- Servicing and maintenance for KUKA, FANUC, ABB robots and many more by our speciality technicians

- KUKA, ABB, FANUC control design

How can Industrial Robots help automate your business?

Join thousands of other Australian companies and manufacturers automating increasing their production with industrial robots. With work health and safety regulations increasing, it is important, now more than ever, to invest in safer, more efficient ways to handle materials.

Robycs Technology are experts in implementing the following systems for your business:

- Box opening robots

- Food packing equipment

- Robotic interface design

- Gantry robots

- Palletising robots

- Industrial robotic arms

- Manufacturing robots

Upgrade your business and boost productivity with the latest robotic systems

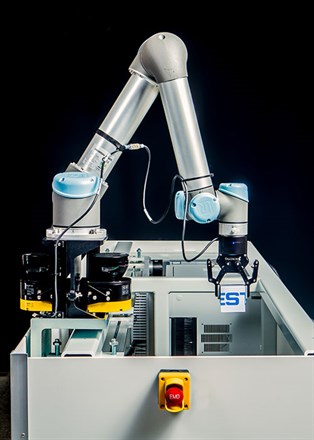

Maximise Safety and Precision with Vision-Equiped Industrial Robotics

Now your machinery can see as well as touch. With Australia at the forefront of implementing industrial robotic vision, you can improve the safety and precision of your processes and your workplace.

Robycs Technology Vision Solutions help companies improve processes. Whether you need your machines to detect problems or integrate elements that are a little off track, we have the vision solutions you need to ensure your products are maximum quality:

- Object Identification and 3D Profiling

- Character Recognition

- Colour Analysis

- Error Proofing

- Distance Tracking

- Orientation Data analysis

- Barcode Reading

- 2D Matrix Code Reading

- 3D Volume Calculation

- 3D Surface Control Calculation

Industrial Robotic Automation Solutions for your Business.

Contact us today.

"We respond to all enquiries the same business day. Please contact us below, we're looking forward to discussing your project with you."

- Raymond Sanchez, CEO.