As Industry 4.0 advances worldwide, agile manufacturers align business strategy with industrial robots to build operational resilience, explore new functions, and secure a competitive edge globally. They are also unknowingly creating new records. An impressive 2.7 million robots are currently operating in factories worldwide – a 12% increase that is the third-highest volume ever recorded.

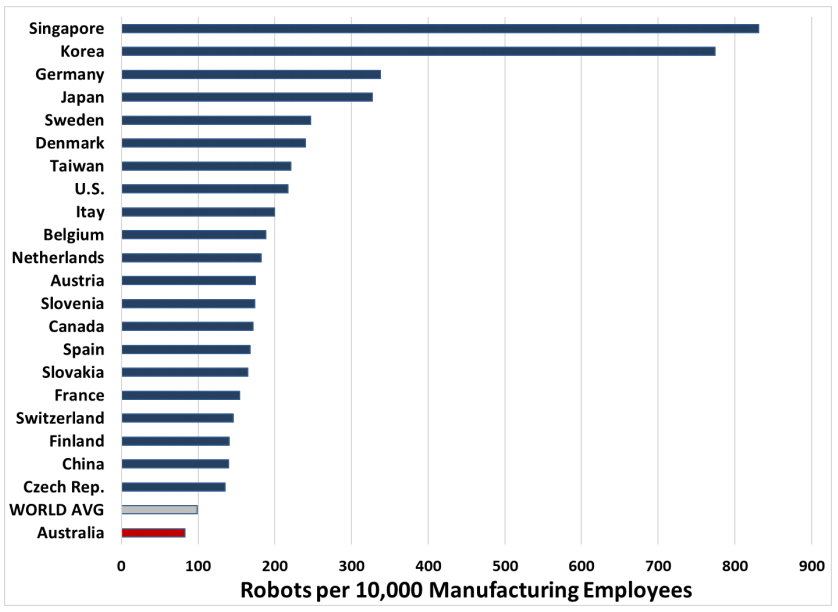

In Australia, however, the installation of robotic machinery has been surprisingly modest. Despite having a track record in the manufacturing industry, Australia has the lowest use of automation worldwide, with just 83 robots in service for every 10 000 workers. Many economic peer countries have installed more robot technology, indicating a strong need to close the ambition gap in Australia and level the playing field.

Worldwide use of Industrial Robots (The Australia Institute, 2020)

But where does one begin?

The good news is that whilst closing the ambition gap to scale the use of robotic machinery does present a series of challenges; numerous opportunities continue to go untapped in Australia. Forward-thinking Australian Manufacturers that leverage human-machine interactions can increase efficiency, improve work quality and ensure less downtime – important factors that drive product quality and build a stronger brand identity.

In this article, you’ll get a better understanding of how to scale your business operations by considering the following points:

- The business case for robots in your operations

- How to set clear goals

- How to choose a the right robotics Integrator

- Testing, retesting and scaling

Step 1: Build a Strong Short-term and Long-term Business Case for Using Industrial Robots

Some decisions around automation stop at the first mention of upfront investment costs. Whilst, costs are an integral part of business — “you have to spend money to make money” — they are only one element of a business case. Resilience, efficiency, safety, and employee engagement are essential factors that should also contribute to your business case and defining your return on investment (ROI) for new robot equipment.

Business resilience determines how quickly your operation recovers from potential setbacks without suffering considerable quality and quantity losses. The more resilient your process, the more competitive your business is to maintain a strong brand identity during a crisis. To integrate resilience into your business case, identify the weakest links in your current operation and potential losses you could have if these continue to be part of your existing business model. Ask yourself: How many repetitive and manual processes are you currently running? How long does it take to do these tasks? How much do these operations affect business continuity? These and other questions will reveal a series of short-term and long-term tangible and intangible risks/benefits that underpin the core of your business case.

Employee engagement affects efficiency, output, and brand identity. Are your employees engaged, or are they being weighed down with manual, repetitive, and dangerous tasks that ebb away at their motivation? Can these tasks be performed with a cobot or a robot to free up employee time and focus where they are most needed in your business?

Step 2: Set Clear Goals and Know When Investing in Robotics makes sense

Not every task can or should be automated with a robot. For example, tasks that require empathy involves some level of unpredictability, and are interactive may not be suited for automation. On the other hand, tasks characterised by routine, predictability, and having established criteria to be completed can benefit from automation.

Palletising is an example of a repetitive routine task where a robotic arm is being used to scale operations, guarantee speed, ensure precision, and fulfil output requests. Robotic palletisers automate the process of putting corrugated carton or other packages onto pallets according to different payload and reach criteria. The user defines a specific pattern to stack different pallets, and the robots use different end-or-arm extensions to grip or apply suction to each load.

Robotic arm using suction grips for package handling

But maybe palletising is not part of your operation. Unprecedented changes in design and industrial robot application have opened doors for new functionalities, such as welding, sealing and gluing, spraying, and cutting. How these applications are embedded in your business will determine the steps to take to deconstruct jobs into specific tasks that can be automated.

Getting a trusted provider to map out your business processes and help identify which segment of the process lifecycle can be automated is a critical step to support robust decision-making. This will save you money and time in the decision-making process, whilst mitigating the risk of choosing robotic machinery that cannot scale as your needs and business change.

In setting goals, consider the following:

- Current business operation and plans for the future to scale a particular area/segment

- Maintenance costs and other additional costs for each new industrial robot

- Flexibility to adapt each robot to perform new tasks and types of modifications to accomplish this

- Current social costs and how these are displaced with industrial robots

Step 3: Partner With a Trusted Robotics Integrator

According to a report from Robotic Vision, difficulty finding the right partner to integrate robots in business operations and lack of in-house staff with automation skills are some of the reasons cited for Australia’s low deployment of robots.

Understandably, the road to automation is not one to be taken alone. Finding the right partner to integrate industrial robots in your business involves a series of steps that continually build on your business case to automate some or all of your operations. Whether these steps include reduced product damage, less downtime, better efficiency or accuracy, these are all an extension of your business case.

A trusted provider should be one who understands the mechanical, electrical, and programming aspects of robotic machinery and who can assess your current operations to identify constraints on these three elements. They should help you to answer the following questions:

- What types of modifications will you need to your existing electrical systems to cater for the extra load a robot will create?

- How will you need to modify your existing space to integrate robotic machinery and what impact will this have on your operations?

- What are some of the hidden costs (maintenance and upgrades) that you should consider?

- Which type of robot models are best suited for your needs and how easy will it be to repurpose these models?

- Which types of tasks in your current operation are best suited for automation and what is the most efficient way to get this done?

Your solutions partner should be an expert with global robot brands so that you are not locked into one particular solution. By being offered a wider spectrum of different brands, you’ll also have better flexibility with your budget to see which solution is more cost-effective. Again this important detail will strengthen your business case for industrial automation.

Step 4: Test, Retest and Scale

Once you’ve decided on the type of robot technology to integrate into your business, the next step is performing a test before scaling to more extensive parts of your business. This reduces risks and allows you to make the necessary modifications to optimise results.

It’s essential to work closely with an experienced robotics integrator at this stage to test and retest your choice of robot equipment. Things to look for at this stage include:

- Efficiency: Does the robot perform according to plan or better?

- Delays: Are there noted delays in response time between different processes and how can these be resolved?

- Employee interaction: Will your employees need more training to interact with the robot?

- Advancement: Can you say that the process has been optimised and ready to be deployed on a broader scale?

How Can Robycs Technology Help?

Robycs Technology helps businesses navigate robotic automation by reducing uncertainty and connecting you with the right expertise for your operational goals. By understanding production requirements, budgets, and future growth plans, businesses can identify where automation can deliver the greatest value.

With access to automation expertise across leading platforms such as ABB, KUKA, Universal Robots, FANUC, and Mitsubishi, Robycs Technology supports businesses exploring robotic solutions, including palletising, welding, cutting, and material handling. The focus is on scalable automation that improves efficiency today while supporting long-term operational resilience.

To explore whether robotic automation is suitable for your operation, contact Robycs Technology to discuss your requirements.