This isn’t exactly groundbreaking news, but we’re going to say it anyway: steel machinery brings a lot of benefits to the factory floor. This iconic metal is strong, safe, durable, and cost-efficient, making it the go-to choice for a large variety of projects. These span from skyscrapers made from structural steel to precision robotics for industry 4.0 applications.

Steel is the backbone of 21st century civilization. We may be living in the information age, but that doesn’t mean we don’t heavily rely on this metal for a huge portion of our infrastructure, including our IT systems and manufacturing.

But what goes into transforming raw metal into components that are ready to be put into production? How do we take stock metal components, such as sheet metal, metal rods, metal billets, and metal bars, and turn them into a finished product?

In this article, we’re going to give you a step-by-step tour to show you how Robycs Technology goes from concept and design all the way to distribution. Let’s start fabricating some steel!

Step 1: Ideation

Before we even touch a piece of metal, we’ll assemble key stakeholders and our engineer team to brainstorm concepts, nail down details, and develop a vision for the end product. Taking time to carefully plan and scope a project makes sure that everyone is on the same page and prevents many mistakes down the road.

Step 2: Concept Design

Now that we’re aligned on our goals, we get to work on concept design. We’ll develop 3D CAD representations of the product and then review them to verify requirements, specifications, and compliance. When this process is over, we’ll have a clear picture of what the finished product will look like.

Step 3: Shot Blasting

Before we start fabricating, we need to clean, strengthen, and polish our metal. This involves a process called shot blasting, where we essentially blast the steel with a stream of abrasive material.

Step 4: Fabrication

Once we have our prepared metal, we’re ready to begin the fabrication process. This step can involve many different procedures, and which ones we use and the order in which we do them depends on the end product’s desired form. Here’s a few of the basic jobs.

Cutting: Just you would expect, we’ll use a variety of tools—from circular saws to high-precision lasers—to cut the steel into parts. By splitting raw steel into halves, thirds, or even smaller sections, we create parts that are the right size and ready for further fabrication.

Folding: Also called bending, this involves manipulating the metal surface to shape at a specified angle. We may want to fold it into a 90-degree bend or make something that’s blunter.

Welding: Precision welding services join two or more disconnected pieces of steel together. By applying heat to the points where the metal pieces join together, we can create a strong bond between them. From there, we can grind or polish it down to get smooth, clean lines.

Other processes include punching, shearing, stamping, and casting. The end result is a steel component that’s ready for production.

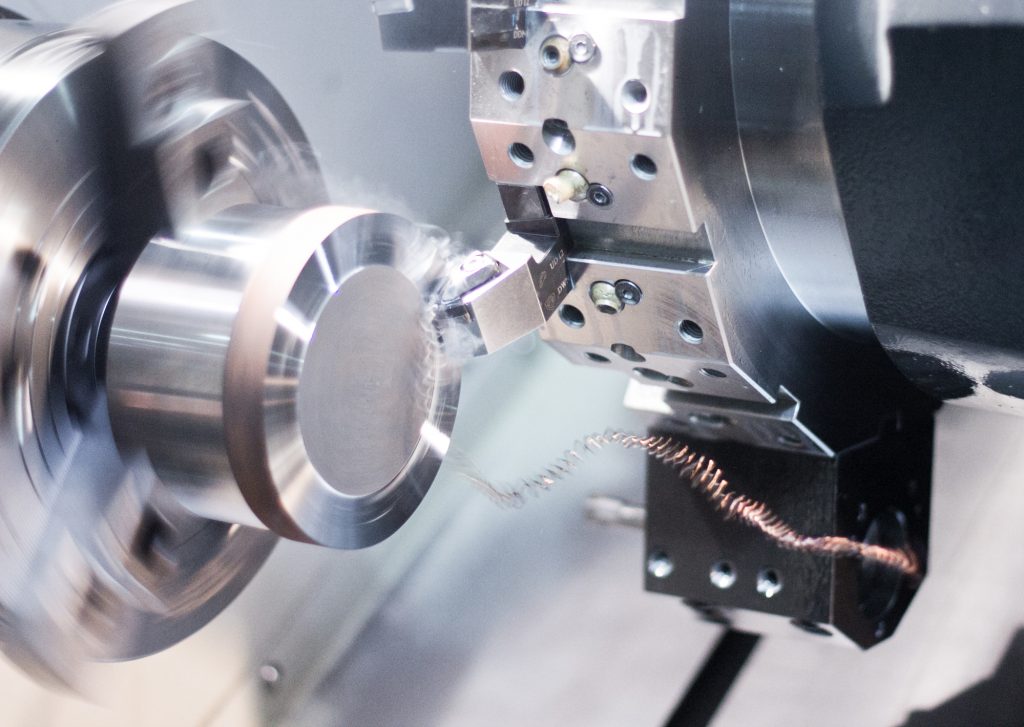

Step 5: CNC Machining

While this step technically falls under the fabrication process, we want to draw special attention to it because it’s so crucial to achieving the fine details that Robycs Technology is known for. CNC machining utilizes computer-controlled lasers to precision etch customized parts and components. While this process isn’t as common for steel manufacturers who specialize in structural steel, it’s one of the most important steps of steel fabrication for industrial control.

Step 6: Assembly

We can complete a full or partial assembly once the fabrication process is over by joining or attaching components. At this point, we’re just ensuring proper assembly of the product and making sure that everything is present and functioning. By assembling the product, we can move on to the next step that allows us to test its operability.

Step 7: Verification

Robycs Technology takes pride in our high quality standards, so every batch of metal fabrication goes through strict quality assurance before it ever leaves our door. We conduct stress tests, feature checks, and other measurements to ensure that our product meets the client’s exact specifications.

Step 8: Finishing

With all functional requirements guaranteed, we’re ready to put the final touches on the product. This can mean applying a special paint job or powder coat, conducting sandblasting to give a smooth, polished finish, or some other finish.

Step 9: Prepare for Shipping

Once we’re 100% confident in our steel products, we’ll disassemble the components and prepare them for direct shipping. During this step, we also take care to efficiently pack all components so that assembly is easy and straightforward once the parts arrive at the plant.

Step 10: Direct Shipping

With everything packed up and ready to go, the only step remaining is securely transporting the finished product. It’s time to start building!

Conclusion

While companies like Robycs Technology employ the latest metal fabrication technologies to create highly detailed products to exacting specifications, we’re proud to carry on a long history of metal fabrication. Since ancient history, we’ve measured technological progress in our ability to fabricate metal. This includes the earliest civilizations that melted and beat copper into various tools, as well as its eventual replacement by bronze age blacksmithing and beyond.

We’re happy to bring this tradition well into the digital age. We cannot forget that the robotics and other mechanical systems that will propel us into the future are created out of metal, and a finished product is only as strong as the material that goes into it. That’s why we never compromise on quality.

We’ve been helping Australian businesses since 1991, and we’re experts at precision metal fabrication. If you’ve got a project or a part that you need built to tight-tolerances and quality matters, contact us to find out how Robycs Technology can help your business.