Steel remains one of the most important materials in modern manufacturing. Its strength, durability and cost efficiency make it essential across industries ranging from large-scale infrastructure to precision robotics and Industry 4.0 applications.

While steel plays a foundational role in manufacturing and industrial systems, transforming raw steel into production-ready components involves a series of carefully planned and executed stages. These typically include design, preparation, fabrication, machining, verification, and delivery.

This article provides a step-by-step overview of the steel fabrication process, helping manufacturers and industrial businesses better understand how stock materials such as sheet metal, billets and bars are converted into finished components ready for use in demanding environments.

Step 1: Ideation

Steel fabrication projects typically begin with ideation and early planning. This stage involves defining the purpose of the component, identifying operational requirements, and clarifying performance expectations. Careful planning at this point helps reduce risk, avoid design errors, and ensure all stakeholders share a clear understanding of the intended outcome.

Step 2: Concept Design

Once requirements are defined, concept design translates ideas into workable technical solutions. This often includes the creation of 3D CAD models to visualise the component and assess form, fit, and function. Designs are reviewed against specifications, compliance requirements, and practical fabrication considerations before progressing further.

Step 3: Shot Blasting

Before fabrication begins, steel is commonly prepared through surface treatment processes such as shot blasting. This step cleans the material, removes surface contaminants, and improves strength and finish, helping ensure consistent fabrication results and long-term performance.

Step 4: Fabrication

Fabrication is the stage where prepared steel is shaped and formed into component parts. The specific techniques and sequence used depend on the final application and design requirements. Common fabrication processes include:

Cutting: Steel is cut to size using methods ranging from mechanical saws to high-precision laser cutting. Breaking raw steel into accurately sized sections ensures components are ready for further processing.

Folding (Bending): Folding involves shaping steel at specified angles to achieve the desired form. This may include sharp bends, gradual curves, or structural folds, depending on design requirements.

Welding: Precision welding services join two or more disconnected pieces of steel together. Controlled heat application creates strong, permanent bonds that can be ground or finished for smooth, clean joins.

Additional fabrication techniques may include punching, shearing, stamping, and casting. Once complete, the component is structurally formed and ready for precision finishing or machining where required.

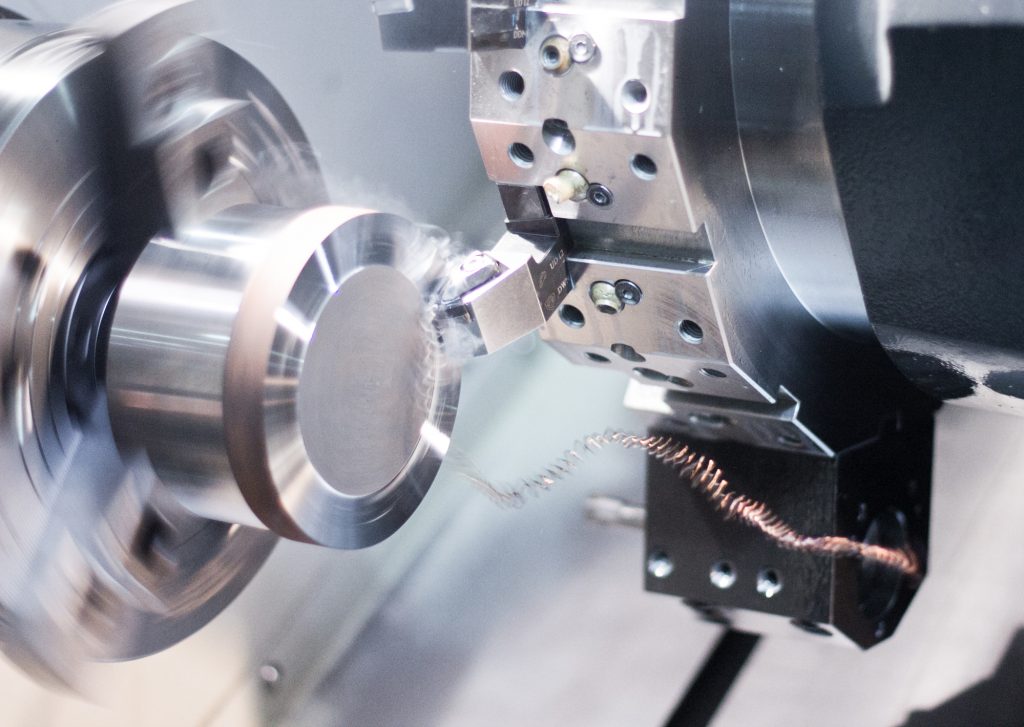

Step 5: CNC Machining

CNC machining is often used to achieve tight tolerances and fine detail not possible through standard fabrication alone. Computer-controlled machining processes allow for precise shaping, drilling, and profiling, making this step particularly important for components used in automation, control systems, and industrial machinery.

Step 6: Assembly

After fabrication and machining, components may be partially or fully assembled. Assembly allows for verification that all parts fit correctly and function as intended before final testing. This step helps identify any issues early and confirms readiness for operational use.

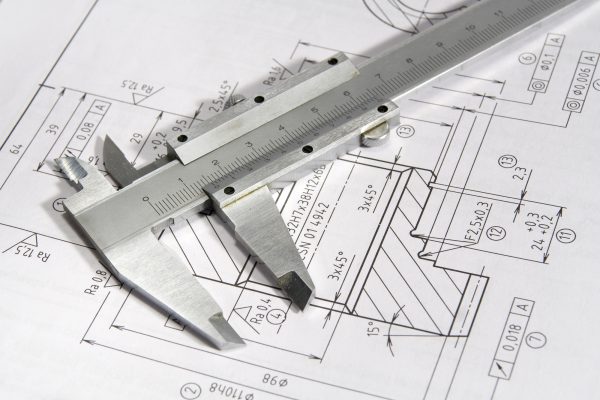

Step 7: Verification

Quality assurance is a critical stage in steel fabrication. Components are typically inspected and tested to confirm they meet design specifications and performance requirements. Verification may include dimensional checks, stress testing, and functional assessments to ensure reliability in demanding industrial environments.

Step 8: Finishing

Once functional requirements are met, finishing processes are applied to improve durability, appearance or environmental resistance. Common finishing techniques include painting, powder coating, polishing or additional surface treatments, depending on the application.

Step 9: Prepare for Shipping

Before delivery, components are prepared to ensure safe handling and transport. This may involve partial disassembly, protective packaging, and clear labelling to support efficient installation or reassembly at the destination site.

Conclusion

Steel fabrication has evolved significantly over time, yet its importance remains unchanged. From early metalworking to modern precision manufacturing, technological progress has consistently relied on the ability to shape metal accurately and reliably.

Today’s robotics, automation systems, and industrial machinery all depend on high-quality fabricated steel components. A finished product is only as strong as the materials and processes used to create it, making quality, verificatio,n and material selection essential at every stage.

Robycs Technology supports Australian manufacturing and industrial businesses by helping them understand fabrication processes and by connecting them with the right expertise to deliver reliable, fit-for-purpose steel components.

If you are planning a steel fabrication project or require custom metal components for an industrial application, contact Robycs Technology to discuss your requirements and explore suitable fabrication solutions.