Complete Metal Fabrication Solutions for Sydney

Design

Fabrication

Installation

Expert industrial electricians with capabilities to install, upgrade and retrofit complicated electrical and mechanical components in your facility.

Sydney Metal Fabrication Services

Stainless Steel Fabrication

Structural Steel Fabrication

Sheet Metal Fabrication

Steel Fabrication

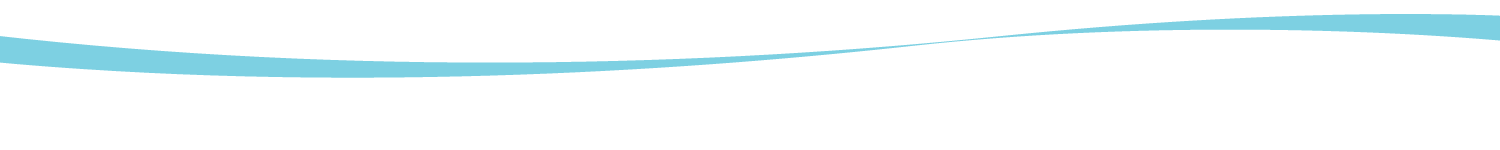

Raw steel is processed into a wide range of components for use in construction, manufacturing and industrial applications. Through precision machining, cutting and welding, metal is transformed into fully functional systems, ready for integration into operational environments.

Aluminium Fabrication

Lighter and boasting a greater strength-to-weight ratio than stainless steel, aluminium requires precise and skilled expertise for proper fabrication because its lower melting point can complicate the welding process and affect the structural integrity of the component.

Metal Fabrication

Specialised Precision Manufacturing Services

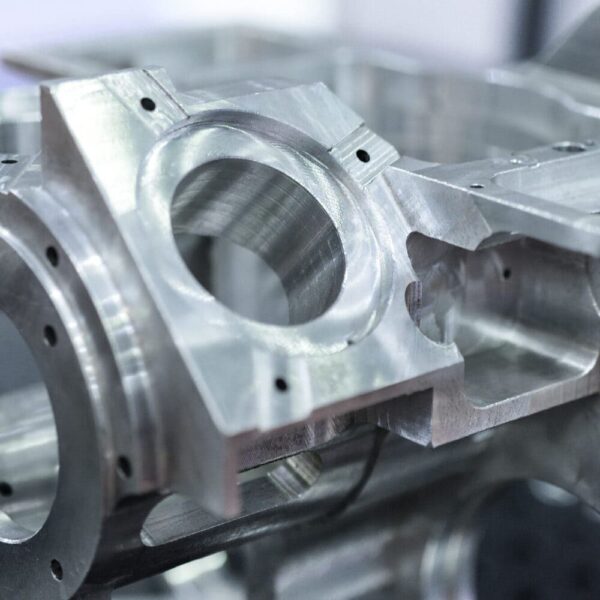

CNC Machining

CNC machining integrates advanced industrial computing with precision tooling to manufacture a wide range of metal components. Essential for high-accuracy 3D cutting applications, CNC machining offers speed, efficiency and repeatable precision.

CNC machining also enables the production of custom components directly from 2D and 3D CAD designs, supporting complex geometries and tight tolerances across diverse industries.

Laser Cutting

Welding

Welding is a critical process within metal fabrication, involving the fusion of compatible metals to form strong, long-lasting joints. It is essential for producing structurally sound and durable components.

By combining quality materials with skilled workmanship, welding services are delivered with a focus on precision, efficiency, and reliability, ensuring consistent performance across industrial and commercial applications.

Additive Manufacturing

Additive manufacturing, commonly referred to as 3D printing, is an advanced metal fabrication technology that enables the production of lighter, stronger components with enhanced structural integrity.

By integrating digital innovation with traditional engineering principles, additive manufacturing supports the development of high-performance parts for demanding applications, offering design flexibility and material efficiency.

Simplifying the Fabrication Process

1. Consultation & Quote

The first step is to understand your project requirements, objectives and timelines. Following a comprehensive initial consultation, you will receive a quote.

2. Design

You can opt to bring your own designs or request the services of a design specialist to engineer a custom solution for your product.

3. Production

Metal fabrication experts and technicians then get right to work on your project. Services include welding, cutting, machining, finishing and more.

4. Quality Assurance

Once your product is finished, it is passed through rigorous quality assurance checks to verify all specifications are met and to check for any deficiencies.

5. Delivery

The final step is to deliver your parts directly to your plant. Expert industrial electrical contractors possess the skills to safely install and set up components and systems on your premises.

Book your consultation and quote today

Please get in touch with us below to get solutions for your project.

By using this form, you consent to your details being forwarded to a licensed contractor for response and fulfilment. Robycs Technology is not a service provider.