Machine Building Capabilities

Custom Machine Design

Custom machines can be designed to exacting specifications to integrate into your existing assembly line to ensure enhanced operational efficiency.

Prototyping

An agile approach to machine building can help design experts iterate upon an initial prototype until the product meets exact specifications

Customised Machine Fabrication

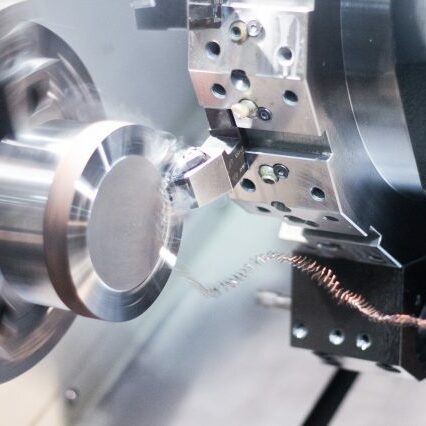

Techniques like CNC machining, welding, and laser cutting are employed to design and manufacture custom machines.

Custom Machines for Manufacturers

Custom machinery is developed to support manufacturers seeking to enhance efficiency, product quality and operational safety through automation. Leveraging expertise across multiple disciplines, including electrical engineering, software development, and mechanical design, these solutions can meet the specific requirements of businesses that depend on purpose-built equipment to optimise their operations.

Engineering and Design Support for your Project

A cross-disciplinary approach to machine development enables the delivery of custom-built machines to meet diverse operational requirements. Services typically begin with comprehensive engineering and design, including electrical schematics, CAD modelling, and system planning. This is followed by stages such as CNC machining, certified welding and fabrication, control panel wiring, PLC programming, mechanical assembly and the application of coatings and finishes.

Final stages may include testing, documentation, and commissioning to ensure the machine performs as intended. Applications range from pneumatic systems and motor control centres to inventory management solutions and specialised automation. Custom machines can be developed to suit a wide variety of industrial needs.

Custom Machine Design

Collaboration with key stakeholders throughout the development process ensures that custom machinery is designed to meet precise technical and operational specifications. Early engagement and ongoing consultation support alignment with project objectives and functional requirements.

Support can extend beyond design to include prototyping, testing, verification and full-scale production. A focus on delivering robust, durable and purpose-built machinery underpins a strong reputation for quality and reliability in custom machine solutions. The goal is to achieve outcomes that align with performance expectations and provide lasting value to industrial operations.

Quality Machine Design and Fabrication

Automation improves overall productivity, increases efficiency and throughput, and bolsters safety for workers on the plant floor by removing them from potentially hazardous environments. Automated machinery leads to a consistent output of high-quality products.

Quality Craftsmanship

Work with a top Australian engineering company that takes pride in their work, paying close attention to details so that nothing slips through the cracks.

Durable Materials

Highest-quality materials, such as steel and other metals, are sourced from verified Australian suppliers. An emphasis on quality to ensure strong machines for long-term use.

Support

Get quality support for the long term at every step of the machine’s lifecycle, including installation, integration, maintenance, and ongoing support.

Customer-Oriented Service

Work with industrial electricians and other support professionals who are the best in their field. They are on standby, day or night, so that you can stay up and running.

Industries Supported

Manufacturing

With Industry 4.0, more manufacturers are embracing automation technology to fuel growth. Choose a trusted machine provider to support your manufacturing operations for long-term success.

Food Processing

Medical

From pharmaceutical to medical device manufacturing, automation is now a key part of the medical industry. Custom machines help manufactures create a consistent product to meet all regulations.

Logistics

From packing and unpacking boxes, to automatic palletising, robotics are a leading force in today's warehousing and logistics sectors. Reduce errors and speed up throughput with automation.

Get a Quote for your Machine Design or Fabrication

Please get in touch with us below to get solutions for your project.

By using this form, you consent to your details being forwarded to a licensed contractor for response and fulfilment. Robycs Technology is not a service provider.