“More than 59% of the manufacturing firms are using some or the other type of robotic technology.”

-PwC

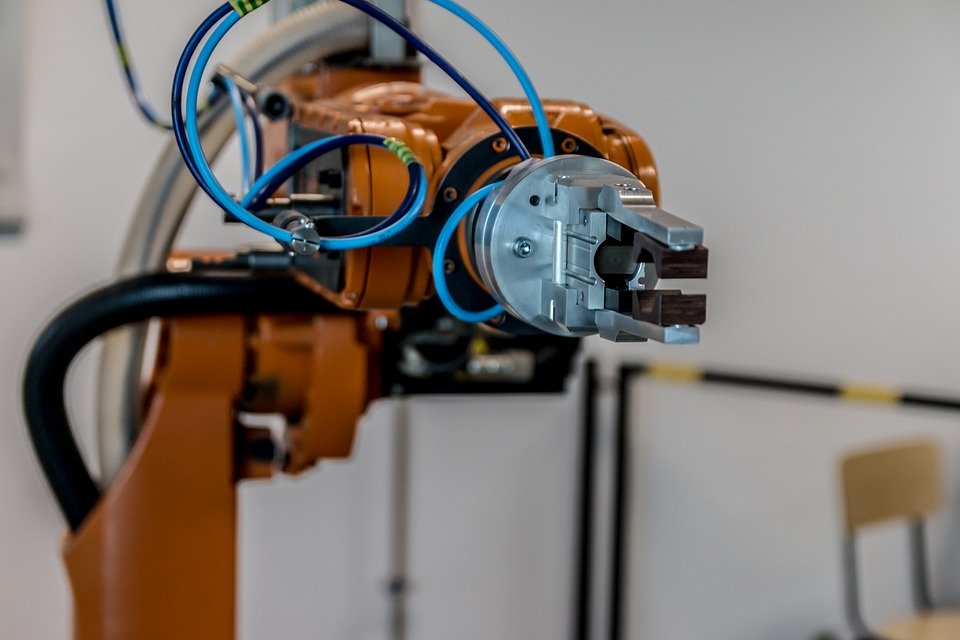

Since its inception, robots have worked hard to bring about a sea of revolution in the manufacturing sector- a sector prone to errors and manufacturing disasters. With every new technological innovation, robots are becoming smarter, faster and cheaper, leaving manufacturing companies in a dilemma of whether to invest in a robot or not.

Automation helps in manufacturing only aids in making the process reliable, faster, cheaper and error-free.

According to BCG, advanced robotics will witness a sharp increase of 10% annually during the next decade because companies will begin to see the economic benefits of the robotic technology.

Here are five irresistible reasons to invest in a robot.

1) Amplifies production output

Leave your robots running overnight and on weekends, and they will work without complaining or taking a break. Even under little supervision, robots can deliver superior results, which humans fail to achieve even under supervision. A robotic solution does not require sick leaves, lunch breaks or maternity leaves and works will full concentration. This enables the manufacturer to complete and process the orders on time.

2) Ameliorates product quality

The inherent quality of robots to perform repeated tasks consistently helps in achieving high product quality, which increases the brand value in the market. Also, robots handle the products and material with precision and accuracy, thereby eliminating any possibility of wasting the resources.

3) Optimum space utilization of space

A plethora of industrial robots has a compact base, which you can easily fit in confined spaces. It reduces the utilization of spaces, and with the real-estate industry at its peak, optimum space utilization saves hundreds of dollars.

4) Enhanced manufacturing flexibility

Robots add a tremendous amount of flexibility to your operations and process control. After programming them once, you can easily switch them between different processes, helping you deliver customized products to the customers. You can easily incorporate design changes and build a long-term customer relationship.

5) Faster and smarter than humans

For a bouquet of processes, robots are faster and more efficient than a human being. For example, in a high volume manufacturing environment such as electrical components and consumer industry, a hundred products are produced on an average every hour. It becomes physically and mentally impossible for a human being to cope up in such a tedious and harsh working environment. This is where a robot will come to your rescue.

Robycs Technology offers a portfolio of services to improve the efficiency and performance of your manufacturing process. Contact us today and choose from an array of custom-built robotic solutions.